In today’s world of high-speed, high-precision packaging automation, robotics are no longer optional—they’re essential. But not all robotic systems are built the same. Depending on your product, line speed, and motion requirements, the type of robot you integrate can make all the difference in performance.

One unique robotic solution in packaging automation is the SCARA robot—a nimble, fast, and space-saving workhorse with capabilities that fill a sweet spot between delta and gantry-style robotics.

What Is a SCARA Robot?

SCARA stands for Selective Compliance Articulated Robot Arm. It’s a four-axis robot that moves primarily in the X-Y plane (with vertical Z-axis motion), making it ideal for pick-and-place applications that require fast, repetitive, and accurate movements.

Unlike delta robots, which use multiple arms suspended from above, or gantry robots that move linearly along rails, SCARA robots have an articulated arm that pivots—like a human elbow—providing incredible speed with a compact footprint.

SCARA vs Gantry vs Delta vs 6-Axis Robots: Which One Fits Your Line?

Each type of industrial robot brings unique motion capabilities, speed, and strengths. Here’s a side-by-side look:

| Feature | SCARA Robot | Delta Robot | Gantry Robot | 6-Axis Robot |

| Speed | Very fast (ideal for light-mid payloads) | Extremely fast (best for lightweight parts) | Moderate speed (heavier payloads) | Moderate (depends on payload & reach) |

| Payload | Light to medium | Light | Medium to heavy | Medium to heavy |

| Footprint | Very compact | Overhead-mounted; needs vertical clearance | Large (due to tracks or beams) | Small base, large reach envelope |

| Movement Style | X-Y-Z with rotational wrist | Parallel link arms (X-Y-Z + rotation) | Linear motion on X, Y, Z axes | Full freedom: X-Y-Z + pitch, yaw, roll |

| Compliance | Rigid vertically, flexible laterally | Rigid | Rigid | Fully articulated, flexible in all axes |

| Ideal For | Tray loading, pick & place, conveyor feeding | High-speed sorting of small lightweight items | Palletizing, heavy product handling | Complex motion tasks, odd angles, intricate placements |

Dive into Paxiom PKR SCARA Applications

Our PKR SCARA robotic machines or systems are developed to meet modern demands for fast, accurate, and space-efficient automation in the cannabis and Consumer Packaged Goods industries. It’s fully integrated into our modular PKR platform, offering smart robotic solutions that are both flexible and easy to install in tight production environments.

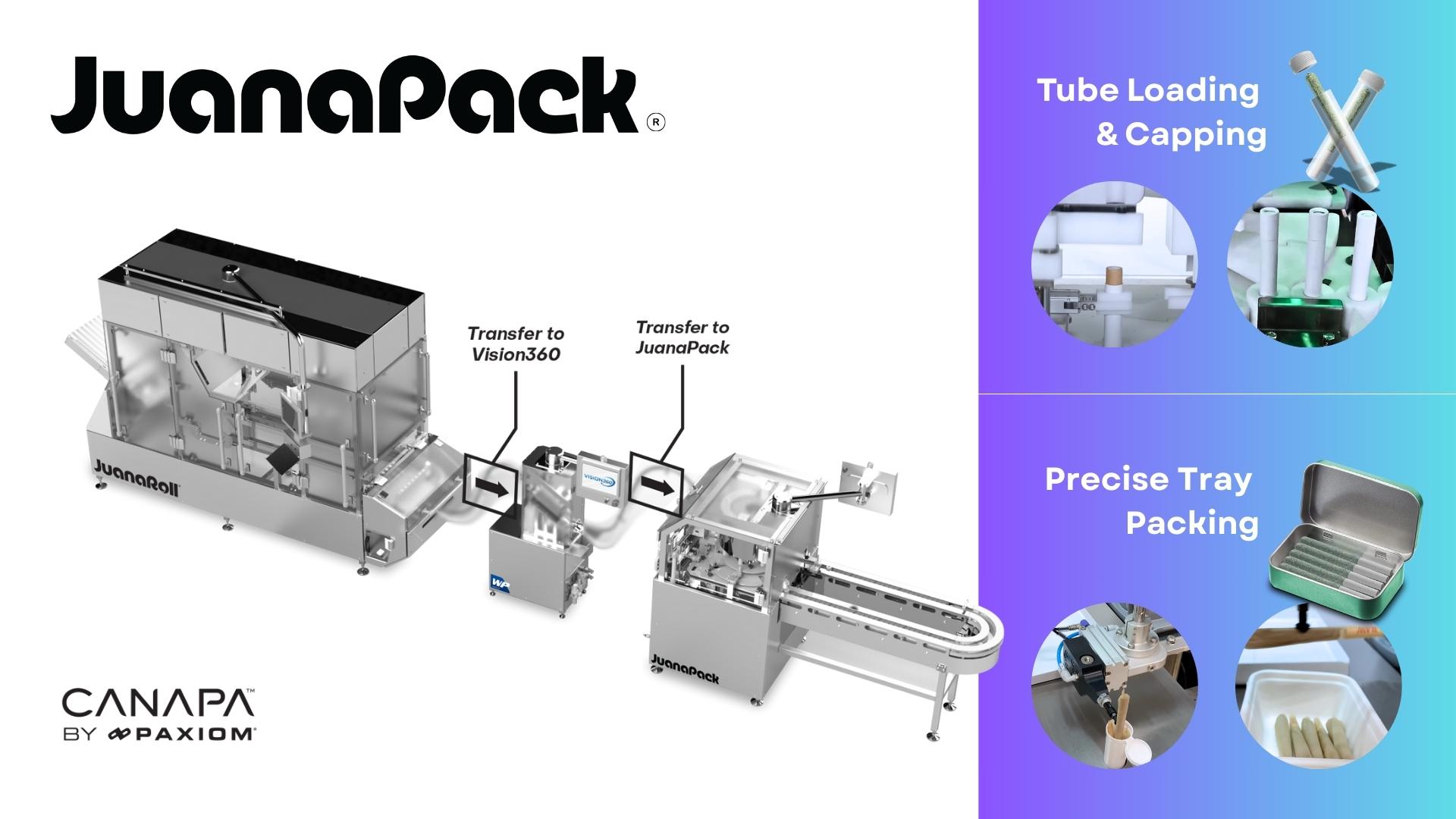

- Pre-Roll Tray Loading with the JuanaPack

In the cannabis industry, automation is quickly becoming key to scaling. Our PKR SCARA robot can be integrated with the JuanaPack machine to create a fully automated pre-roll handling system. Watch the video here.

Here’s how it works:

- Pre-rolls are conveyed to the staging area

- The PKR SCARA robot picks and places each pre-roll into pre-formed trays or tubes

- Custom patterns can be programmed—rows, grids, even rotational orientation

- Result: A fully automated solution for high-output pre-roll packaging, reducing manual labor and boosting consistency

This is especially useful for cannabis producers who want turnkey automation to eliminate touchpoints and increase throughput while maintaining product integrity.

- Automatic Product Feeding to Flow Wrappers

The PKR SCARA isn’t just limited to pre-rolls—it also plays a crucial role in flow wrapping edibles. Watch the PKR SCARA with the Sleek F65 Flow Wrapper

In this application:

- Loose or randomly spaced products are introduced on an infeed belt

- The SCARA robot picks products and accurately places them onto the conveyor of a horizontal flow wrapper

- Perfect spacing and orientation are achieved for consistent wrapping and sealing

This solution drastically reduces the need for manual loading and helps increase production uptime and hygiene compliance.

Why Choose a SCARA Robot for Packaging?

✅ Speed: SCARAs move fast—making them ideal for mid-to-high-speed pick-and-place applications

✅ Precision: Excellent repeatability and gentle handling of delicate items

✅ Compact design: Easily fits into tight floor plans

✅ Flexibility: Can be reprogrammed for different pick patterns or product formats

✅ Cost-effective: Less expensive and easier to maintain than some multi-axis robot arms

Whether you’re automating pre-roll packaging in cannabis or speeding up product loading in food and consumer goods, SCARA robots offer a unique blend of performance and versatility. With Canapa Solutions you get a robotic system that’s plug-and-play ready, reliable, and built to scale as your production grows.

Ready to explore robotics for your packaging line? Let’s build something smart together. Submit an inquiry today: https://www.canapasolutions.com/cannabis-packaging-machine-inquiry/