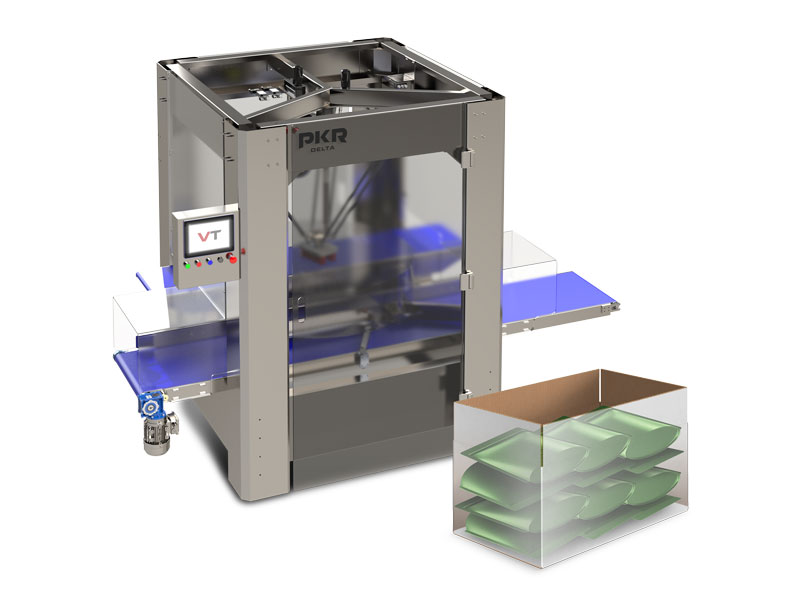

PKR Delta

PICK & PLACE FLEXIBLE POUCHES

Our PKR modular pick & place cell will automatically top-load your flexible bags and packages into cases or trays using our Delta Robot.

Featuring gentle product handling by either vacuum or mechanical means, your product integrity and packing consistency are assured. And we can configure the PKR to accommodate a wide variety of case/tray sizes and pack patterns.

Its modular design allows it to easily fit into any existing production line or integrate it as part of a complete packaging line with our case erecting, tray forming, sealing and robotic palletizing solutions.

Videos

Features:

• Multi axis servo delta robot – non washdown

• Up to 180 picks per minute depending on weight, distance, product and pack style

• Multiple product pick capability per cycle

• One Vacuum End Effector, tailored for your product

• Position Repeatability 0.1mm

• Product infeed conveyor

• Two 400 watt Omron servo drives for conveyor

• Independent conveyor speed control

• Box or tray indexing conveyor

• Box detection sensors, no box, no pick

• Quick end easy End Effector changeover

• Pick up area 1300 mm radius (larger areas available)

• PLC NJ-NX omron with expandable modules

• Touch screen parameter programming

• Recall product setups

• Stainless steel construction

• Enclosed OMRON SMART CAMERA high speed & resolution -3.2 Mpix

• Recognize and store shape, size or graphics

• Interchangeable direction of product and carton conveyors

• Left to right product and carton direction

• Lexan aluminum reinforced access doors with safety cut off

• Compressed air reserve tank integrated for constant air pressure

• Air regulator, lubricator and filter

Delta Specifications:

Payload: 4 kg / 8.8 lbs

Rated Pick Up Area: 1300×400 mm / 51.1 x 15.7 in

Pick & Place Actions (ISO Path): Up to 180 picks per minute

End Effector-Gripper:

Standard: Vacuum suction cups

Custom: Per design and project requirement

*Rates subject to package style, type and size

-

Specifications

-

Features:

• Multi axis servo delta robot – non washdown

• Up to 180 picks per minute depending on weight, distance, product and pack style

• Multiple product pick capability per cycle

• One Vacuum End Effector, tailored for your product

• Position Repeatability 0.1mm

• Product infeed conveyor

• Two 400 watt Omron servo drives for conveyor

• Independent conveyor speed control

• Box or tray indexing conveyor

• Box detection sensors, no box, no pick

• Quick end easy End Effector changeover

• Pick up area 1300 mm radius (larger areas available)

• PLC NJ-NX omron with expandable modules

• Touch screen parameter programming

• Recall product setups

• Stainless steel construction

• Enclosed OMRON SMART CAMERA high speed & resolution -3.2 Mpix

• Recognize and store shape, size or graphics

• Interchangeable direction of product and carton conveyors

• Left to right product and carton direction

• Lexan aluminum reinforced access doors with safety cut off

• Compressed air reserve tank integrated for constant air pressure

• Air regulator, lubricator and filterDelta Specifications:

Payload: 4 kg / 8.8 lbs

Rated Pick Up Area: 1300×400 mm / 51.1 x 15.7 in

Pick & Place Actions (ISO Path): Up to 180 picks per minute

End Effector-Gripper:

Standard: Vacuum suction cups

Custom: Per design and project requirement*Rates subject to package style, type and size

-

Ideal Products

-

PouchesBagsTraysCartons

We’re here to help

Want to see your product run on this machine?

PKR GANTRY ROBOT

BOTTLES, JARS, CONTAINERS

Our PKR Gantry pick & place cell will automatically top-load your product into cases or trays using our Gantry Robot.

The robot’s X, Y, Z-axis functionality is the perfect packing solution for your cans, bottles, jars, cartons and more rigid products.

The PKR Gantry uses either vacuum or mechanical means to provide gentle product handling, assuring product integrity and consistent tray and case packing while accommodating a wide variety of case/tray sizes and pack patterns.

Its modular design allows it to easily fit into any existing production line or be integrated as part of a complete packaging line with our case erecting, tray forming, sealing and robotic palletizing solutions.

Videos

Features:

• Gantry robot with X, Y, Z axis

• Heavy-duty welded painted steel construction (stainless steel available)

• Programmable logic controller

• Color touch screen user interface

• Pick & place unit for gentle product handling

• Infeed conveyor for product

• Infeed conveyor for cases or trays

• Quick release change parts for fast product changeovers

• Product staging and loading area

• Full safety interlocked guarding

• Venturi vacuum technology

• Low product and no product detectors on infeed

• Optional servo multi-lane product diverter

*Rates subject to package style, type and size

-

Specifications

-

Features:

• Gantry robot with X, Y, Z axis

• Heavy-duty welded painted steel construction (stainless steel available)

• Programmable logic controller

• Color touch screen user interface

• Pick & place unit for gentle product handling

• Infeed conveyor for product

• Infeed conveyor for cases or trays

• Quick release change parts for fast product changeovers

• Product staging and loading area

• Full safety interlocked guarding

• Venturi vacuum technology

• Low product and no product detectors on infeed

• Optional servo multi-lane product diverter*Rates subject to package style, type and size

-

Ideal Products

-

BottlesContainersJarsCansCartonsTrays

We’re here to help

Want to see your product run on this machine?

PKR Delta

MODULAR PICK & PLACE

Videos

Our PKR modular pick & place cell will automatically top-load your flexible bags and packages into cases or trays using our Delta Robot.

Featuring gentle product handling by either vacuum or mechanical means, your product integrity and packing consistency are assured. And we can configure the PKR to accommodate a wide variety of case/tray sizes and pack patterns.

Its modular design allows it to easily fit into any existing production line or integrate it as part of a complete packaging line with our case erecting, tray forming, sealing and robotic palletizing solutions.

Mechanical Rates:

1 pick: Up to 50 per minute

2 picks: Up to 80 per minute

*Rates subject to package style, type and size

Cannabis dry flower

Infused/CBD gummies

Infused/CBD cookies

Infused/CBD brownies

Infused/CBD wrapped candies

Pre-roll tubes

Infused/CBD chocolates

Baked Edibles

Milled Cannabis

CBD pet treats

CBD skincare

Infused/CBD beverage mix

-

Specifications

-

Mechanical Rates:

1 pick: Up to 50 per minute

2 picks: Up to 80 per minute*Rates subject to package style, type and size

-

Ideal Products

-

Cannabis dry flower

Infused/CBD gummies

Infused/CBD cookies

Infused/CBD brownies

Infused/CBD wrapped candies

Pre-roll tubes

Infused/CBD chocolates

Baked Edibles

Milled Cannabis

CBD pet treats

CBD skincare

Infused/CBD beverage mix

PKR GANTRY ROBOT

PICK & PLACE

Videos

Our PKR Gantry pick & place cell will automatically top-load your product into cases or trays using our Gantry Robot.

The robot’s X, Y, Z-axis functionality is the perfect packing solution for your cans, bottles, jars, cartons and more rigid products.

The PKR Gantry uses either vacuum or mechanical means to provide gentle product handling, assuring product integrity and consistent tray and case packing while accommodating a wide variety of case/tray sizes and pack patterns.

Its modular design allows it to easily fit into any existing production line or be integrated as part of a complete packaging line with our case erecting, tray forming, sealing and robotic palletizing solutions.

Max Mechanical Rates

CS-BNB (Bag-in-Box):22 cycles per minute

CS-BD (Belt Drive): 22 cycles per minute

*Rates subject to package style, type and size

Cannabis dry flower

Infused/CBD gummies

Infused/CBD cookies

Infused/CBD brownies

Infused/CBD wrapped candies

Pre-roll tubes

Infused/CBD chocolates

Baked Edibles

Milled Cannabis

CBD pet treats

CBD skincare

Infused/CBD beverage mix

-

Specifications

-

Max Mechanical Rates

CS-BNB (Bag-in-Box):22 cycles per minute

CS-BD (Belt Drive): 22 cycles per minute

*Rates subject to package style, type and size

-

Ideal Products

-

Cannabis dry flower

Infused/CBD gummies

Infused/CBD cookies

Infused/CBD brownies

Infused/CBD wrapped candies

Pre-roll tubes

Infused/CBD chocolates

Baked Edibles

Milled Cannabis

CBD pet treats

CBD skincare

Infused/CBD beverage mix