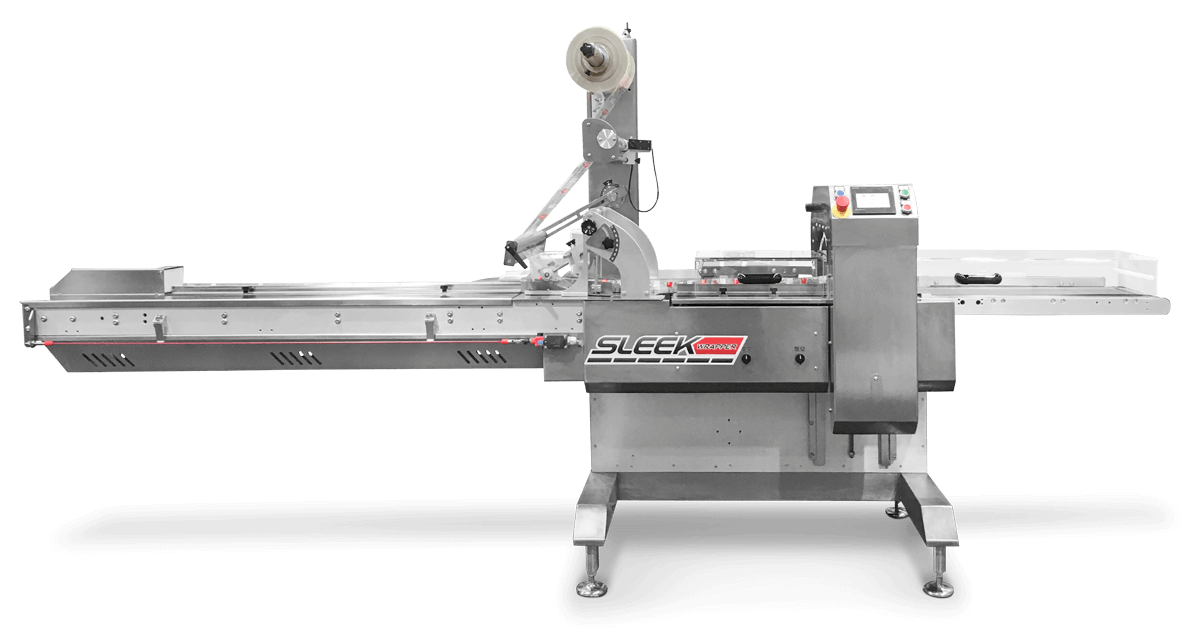

SLEEK 40

THE MOST COMPACT FLOW WRAPPER

The SleekWrapper 40 horizontal wrapping machine is designed with reliability, simplicity and serviceability in mind. This machine will produce up to 120 packages per minute with a maximum web width of 15.5 inches or 400mm. The Sleek 40 features quick, easy changeover and adjustment that minimizes product and film waste and reduces maintenance costs. Four servo-driven motors assure precise positioning with smooth acceleration and deceleration.

Our machines come standard with stainless steel frame construction, user-friendly color touchscreen, automatic open/close rotary fin wheel assembly, rotary seal jaws with jam detecting logic and the ability to preprogram and store product settings.

Videos

Features

- Stainless steel frame construction

- Full servo-driven by 3 servo motors

- Belt Driven

- Infeed conveyor with snap-in pushers for fast changeovers

- Cantilevered single film holder

- Color touch screen HMI and Mitsubishi PLC

- Pre-programmable controls for up to 100 recipes

- Auto open / close rotary fin wheel assembly when machine stops

- Temperature control

- Rotary seal jaws

- Automatic synchronization of crimper after jams

- Optional No Product / No Bag

- Optional No Gap / No Seal for misplaced products

MAX MECHANICAL RATES (NO PRODUCT)

1-up jaw: 50 per minute

2-up jaw: 80 per minute

Infused/CBD gummies

Infused/CBD chocolates

Infused/CBD cookies

Infused/CBD brownies

Infused/CBD candy bars

Infused/CBD baked goods

-

Specifications

-

Features

- Stainless steel frame construction

- Full servo-driven by 3 servo motors

- Belt Driven

- Infeed conveyor with snap-in pushers for fast changeovers

- Cantilevered single film holder

- Color touch screen HMI and Mitsubishi PLC

- Pre-programmable controls for up to 100 recipes

- Auto open / close rotary fin wheel assembly when machine stops

- Temperature control

- Rotary seal jaws

- Automatic synchronization of crimper after jams

- Optional No Product / No Bag

- Optional No Gap / No Seal for misplaced products

MAX MECHANICAL RATES (NO PRODUCT)

1-up jaw: 50 per minute

2-up jaw: 80 per minute

-

Ideal Products

-

Infused/CBD gummies

Infused/CBD chocolates

Infused/CBD cookies

Infused/CBD brownies

Infused/CBD candy bars

Infused/CBD baked goods

We’re here to help

Want to see your product run on this machine?

SLEEK 45

HIGH SPEED

The high-speed SleekWrapper 45 horizontal wrapping machine is designed with reliability, simplicity and serviceability in mind. This machine will produce up to 160 packages per minute (subject to jaw configuration and product size) with a maximum web width of 18 inches or 450mm.

The Sleek 45 features quick, easy changeover and adjustment that minimizes product and film waste and reduces maintenance costs. Multiple servo-driven motors assure precise positioning with smooth acceleration and deceleration.

This machine comes standard with stainless steel frame construction, user-friendly color touchscreen, automatic open/close rotary fin wheel assembly, rotary seal jaws with jam detecting logic and the ability to preprogram and store product settings.

Videos

Features

- Stainless steel frame construction

- Full servo-driven by 3 servo motors

- Belt Driven

- Infeed conveyor with snap-in pushers for fast changeovers

- Cantilevered single film holder

- Color touch screen HMI and Mitsubishi PLC

- Pre-programmable controls for up to 100 recipes

- Auto open / close rotary fin wheel assembly when machine stops

- Temperature control

- Rotary seal jaws

- Automatic synchronization of crimper after jams

- Optional No Product / No Bag

- Optional No Gap / No Seal for misplaced products

*Rates subject to package style, type and size

Infused/CBD gummies

Infused/CBD chocolates

Infused/CBD cookies

Infused/CBD brownies

Infused/CBD candy bars

Infused/CBD baked goods

-

Specifications

-

Features

- Stainless steel frame construction

- Full servo-driven by 3 servo motors

- Belt Driven

- Infeed conveyor with snap-in pushers for fast changeovers

- Cantilevered single film holder

- Color touch screen HMI and Mitsubishi PLC

- Pre-programmable controls for up to 100 recipes

- Auto open / close rotary fin wheel assembly when machine stops

- Temperature control

- Rotary seal jaws

- Automatic synchronization of crimper after jams

- Optional No Product / No Bag

- Optional No Gap / No Seal for misplaced products

*Rates subject to package style, type and size

-

Ideal Products

-

Infused/CBD gummies

Infused/CBD chocolates

Infused/CBD cookies

Infused/CBD brownies

Infused/CBD candy bars

Infused/CBD baked goods

We’re here to help

Want to see your product run on this machine?

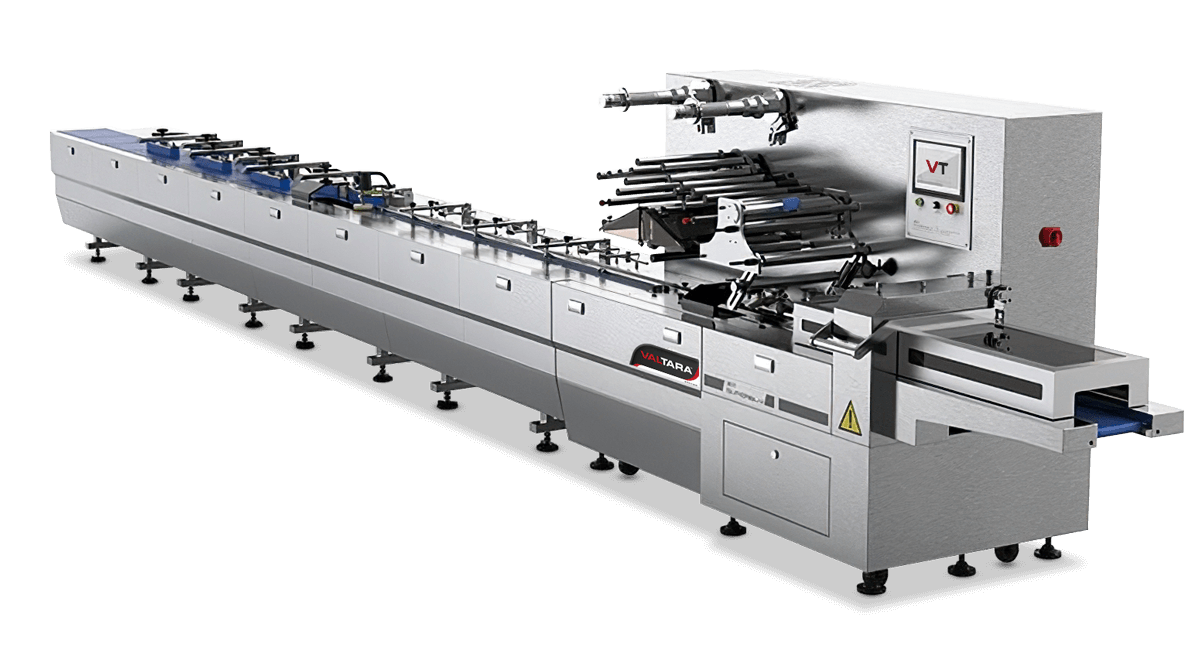

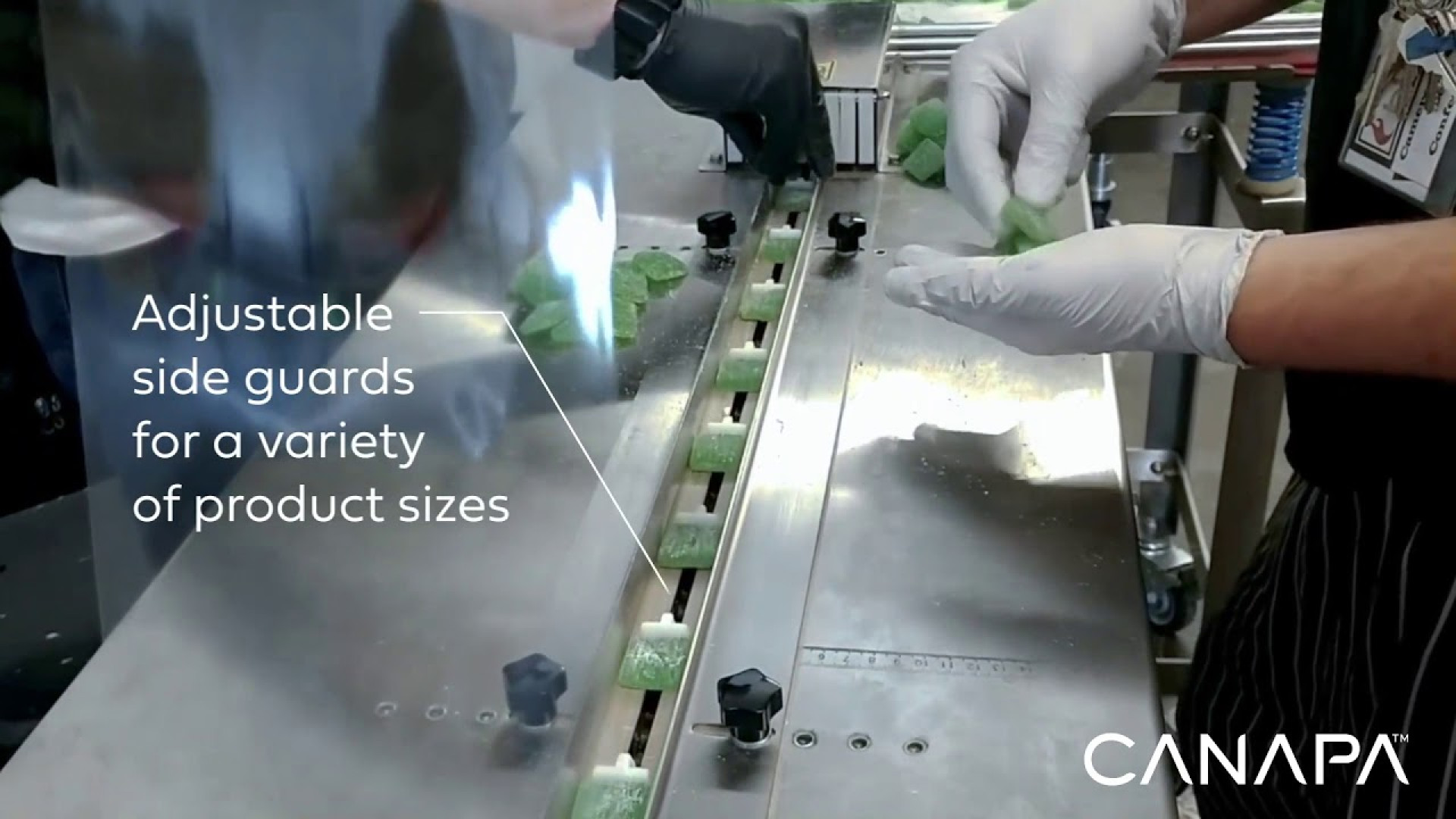

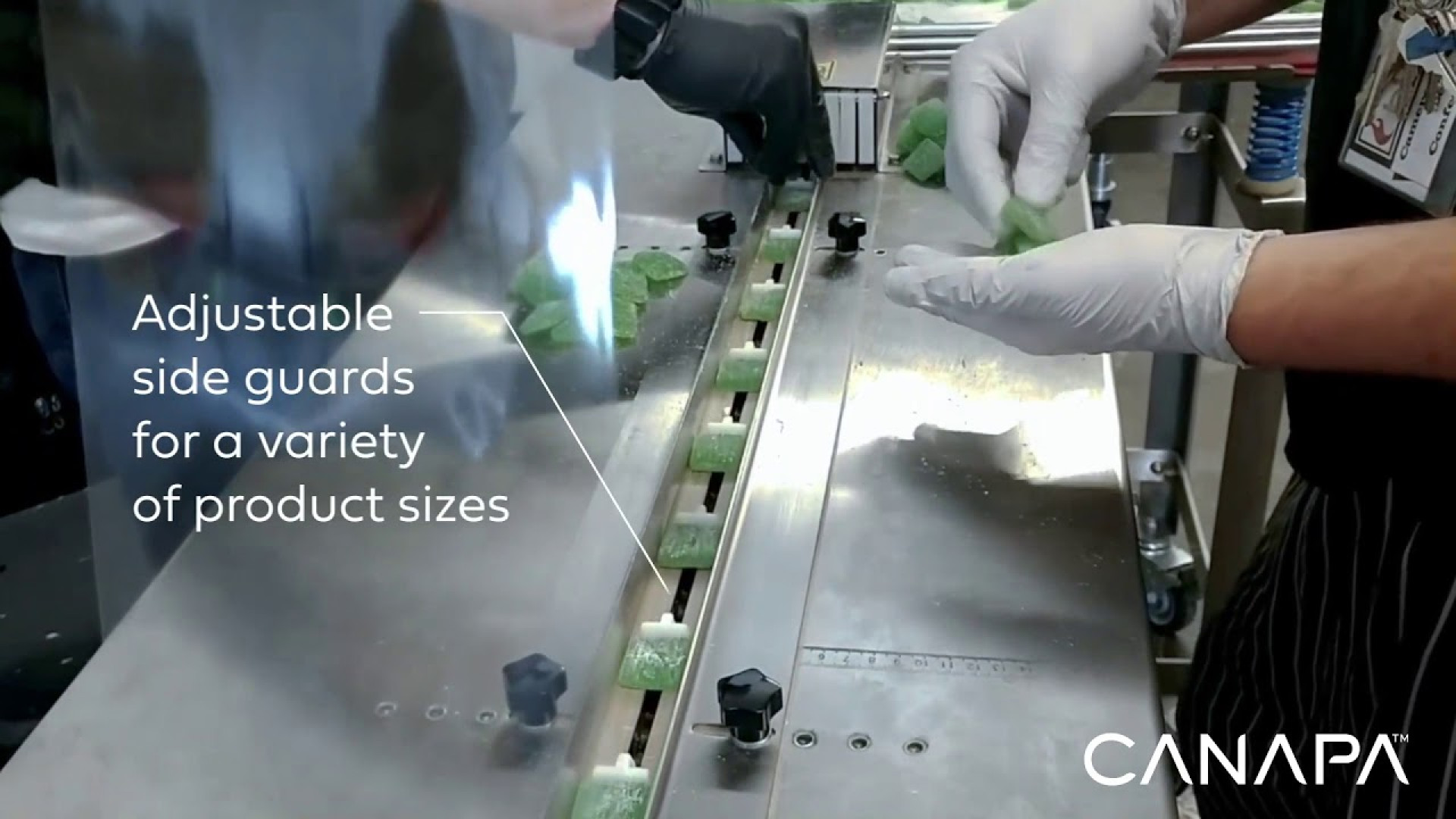

SLEEK HSA

CHICANE PRODUCT ALIGNER

The SleekWrapper HSA with chicane product aligner high-speed flow wrapper is engineered to accurately load, align and wrap product according to your project specifications. This reliable system is perfect for wrapping infused candies, chocolates and baked goods such as cookies and brownies while remaining easy to operate and maintain.

Standard features include a photoelectric automatic detection and servo dosing system, stainless steel frame construction and a 10-inch touchscreen. A second film roll can be added upon request.

Videos

Features

- Advanced full servo motor and driver control system for easy maintenance, low failure rate and stable performance.

- Large color touch screen and PLC controls

- Equipped with photoelectric automatic detection and servo dosing system.

- With automatic acceleration and deceleration, automatic fill function, accurate positioning, no empty package.

- Stainless steel sheet metal exterior – 304

- Integrated system design

- Second film roll support

- Automatic film splicing

*Rates subject to package style, type and size

Infused/CBD gummies

Infused/CBD chocolates

Infused/CBD cookies

Infused/CBD brownies

Infused/CBD candy bars

-

Specifications

-

Features

- Advanced full servo motor and driver control system for easy maintenance, low failure rate and stable performance.

- Large color touch screen and PLC controls

- Equipped with photoelectric automatic detection and servo dosing system.

- With automatic acceleration and deceleration, automatic fill function, accurate positioning, no empty package.

- Stainless steel sheet metal exterior – 304

- Integrated system design

- Second film roll support

- Automatic film splicing

*Rates subject to package style, type and size

-

Ideal Products

-

Infused/CBD gummies

Infused/CBD chocolates

Infused/CBD cookies

Infused/CBD brownies

Infused/CBD candy bars

We’re here to help

Want to see your product run on this machine?

SLEEK 40

THE MOST COMPACT FLOW WRAPPER

Videos

The SleekWrapper 40 horizontal wrapping machine is designed with reliability, simplicity and serviceability in mind. This machine will produce up to 120 packages per minute with a maximum web width of 15.5 inches or 400mm. The Sleek 40 features quick, easy changeover and adjustment that minimizes product and film waste and reduces maintenance costs. Four servo-driven motors assure precise positioning with smooth acceleration and deceleration.

Our machines come standard with stainless steel frame construction, user-friendly color touchscreen, automatic open/close rotary fin wheel assembly, rotary seal jaws with jam detecting logic and the ability to preprogram and store product settings.

Features

- Stainless steel frame construction

- Full servo-driven by 3 servo motors

- Belt Driven

- Infeed conveyor with snap-in pushers for fast changeovers

- Cantilevered single film holder

- Color touch screen HMI and Mitsubishi PLC

- Pre-programmable controls for up to 100 recipes

- Auto open / close rotary fin wheel assembly when machine stops

- Temperature control

- Rotary seal jaws

- Automatic synchronization of crimper after jams

- Optional No Product / No Bag

- Optional No Gap / No Seal for misplaced products

MAX MECHANICAL RATES (NO PRODUCT)

1-up jaw: 50 per minute

2-up jaw: 80 per minute

Infused/CBD gummies

Infused/CBD chocolates

Infused/CBD cookies

Infused/CBD brownies

Infused/CBD candy bars

Infused/CBD baked goods

-

Specifications

-

Features

- Stainless steel frame construction

- Full servo-driven by 3 servo motors

- Belt Driven

- Infeed conveyor with snap-in pushers for fast changeovers

- Cantilevered single film holder

- Color touch screen HMI and Mitsubishi PLC

- Pre-programmable controls for up to 100 recipes

- Auto open / close rotary fin wheel assembly when machine stops

- Temperature control

- Rotary seal jaws

- Automatic synchronization of crimper after jams

- Optional No Product / No Bag

- Optional No Gap / No Seal for misplaced products

MAX MECHANICAL RATES (NO PRODUCT)

1-up jaw: 50 per minute

2-up jaw: 80 per minute

-

Ideal Products

-

Infused/CBD gummies

Infused/CBD chocolates

Infused/CBD cookies

Infused/CBD brownies

Infused/CBD candy bars

Infused/CBD baked goods

SLEEK 45

HIGH SPEED

Videos

The high-speed SleekWrapper 45 horizontal wrapping machine is designed with reliability, simplicity and serviceability in mind. This machine will produce up to 160 packages per minute (subject to jaw configuration and product size) with a maximum web width of 18 inches or 450mm.

The Sleek 45 features quick, easy changeover and adjustment that minimizes product and film waste and reduces maintenance costs. Multiple servo-driven motors assure precise positioning with smooth acceleration and deceleration.

This machine comes standard with stainless steel frame construction, user-friendly color touchscreen, automatic open/close rotary fin wheel assembly, rotary seal jaws with jam detecting logic and the ability to preprogram and store product settings.

Features

- Stainless steel frame construction

- Full servo-driven by 3 servo motors

- Belt Driven

- Infeed conveyor with snap-in pushers for fast changeovers

- Cantilevered single film holder

- Color touch screen HMI and Mitsubishi PLC

- Pre-programmable controls for up to 100 recipes

- Auto open / close rotary fin wheel assembly when machine stops

- Temperature control

- Rotary seal jaws

- Automatic synchronization of crimper after jams

- Optional No Product / No Bag

- Optional No Gap / No Seal for misplaced products

*Rates subject to package style, type and size

Infused/CBD gummies

Infused/CBD chocolates

Infused/CBD cookies

Infused/CBD brownies

Infused/CBD candy bars

Infused/CBD baked goods

-

Specifications

-

Features

- Stainless steel frame construction

- Full servo-driven by 3 servo motors

- Belt Driven

- Infeed conveyor with snap-in pushers for fast changeovers

- Cantilevered single film holder

- Color touch screen HMI and Mitsubishi PLC

- Pre-programmable controls for up to 100 recipes

- Auto open / close rotary fin wheel assembly when machine stops

- Temperature control

- Rotary seal jaws

- Automatic synchronization of crimper after jams

- Optional No Product / No Bag

- Optional No Gap / No Seal for misplaced products

*Rates subject to package style, type and size

-

Ideal Products

-

Infused/CBD gummies

Infused/CBD chocolates

Infused/CBD cookies

Infused/CBD brownies

Infused/CBD candy bars

Infused/CBD baked goods

SLEEK HSA

CHICANE PRODUCT ALIGNER

Videos

The SleekWrapper HSA with chicane product aligner high-speed flow wrapper is engineered to accurately load, align and wrap product according to your project specifications. This reliable system is perfect for wrapping candies, chocolates and baked goods such as cookies and brownies while remaining easy to operate and maintain.

Standard features include a photoelectric automatic detection and servo dosing system, stainless steel frame construction and a 10-inch touchscreen. A second film roll can be added upon request.

Features

- Advanced full servo motor and driver control system for easy maintenance, low failure rate and stable performance.

- Large color touch screen and PLC controls

- Equipped with photoelectric automatic detection and servo dosing system.

- With automatic acceleration and deceleration, automatic fill function, accurate positioning, no empty package.

- Stainless steel sheet metal exterior – 304

- Integrated system design

- Second film roll support

- Automatic film splicing

*Rates subject to package style, type and size

Infused/CBD gummies

Infused/CBD chocolates

Infused/CBD cookies

Infused/CBD brownies

Infused/CBD candy bars

-

Specifications

-

Features

- Advanced full servo motor and driver control system for easy maintenance, low failure rate and stable performance.

- Large color touch screen and PLC controls

- Equipped with photoelectric automatic detection and servo dosing system.

- With automatic acceleration and deceleration, automatic fill function, accurate positioning, no empty package.

- Stainless steel sheet metal exterior – 304

- Integrated system design

- Second film roll support

- Automatic film splicing

*Rates subject to package style, type and size

-

Ideal Products

-

Infused/CBD gummies

Infused/CBD chocolates

Infused/CBD cookies

Infused/CBD brownies

Infused/CBD candy bars