JuanaRoll Elevates Production Efficiency and Reliability with ATS Illuminate™ Manufacturing Intelligence Software

Las Vegas, NV — JuanaRoll, a pioneer in automated pre-roll and cannabis production technology, has announced the successful integration of ATS Illuminate™ Manufacturing Intelligence Software, unlocking a new level of data-driven transparency, reliability, and performance across its production operations.

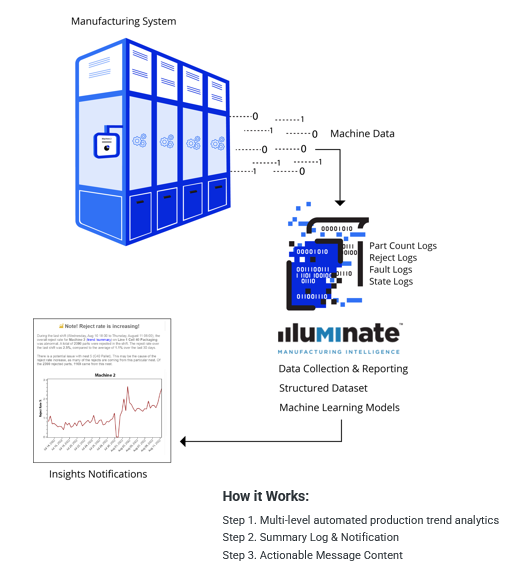

By leveraging ATS’s Illuminate platform, JuanaRoll now gains real-time insight into every aspect of its manufacturing process—from machine health and OEE/MOEE performance to operator efficiency and maintenance readiness. Illuminate enables JuanaRoll to move beyond reactive problem-solving, shifting toward a fully proactive and preventive maintenance strategy that ensures maximum uptime and consistent production quality.

Real-Time Intelligence for Smart Decision-Making

Illuminate’s interactive Dashboard provides an instant view of key production metrics such as OEE, part counts, and machine states, giving JuanaRoll operators and managers the ability to track live performance and pinpoint inefficiencies with precision. With easy drill-down features, teams can quickly move from top-line visibility to detailed root-cause analysis.

Comprehensive Performance Summaries

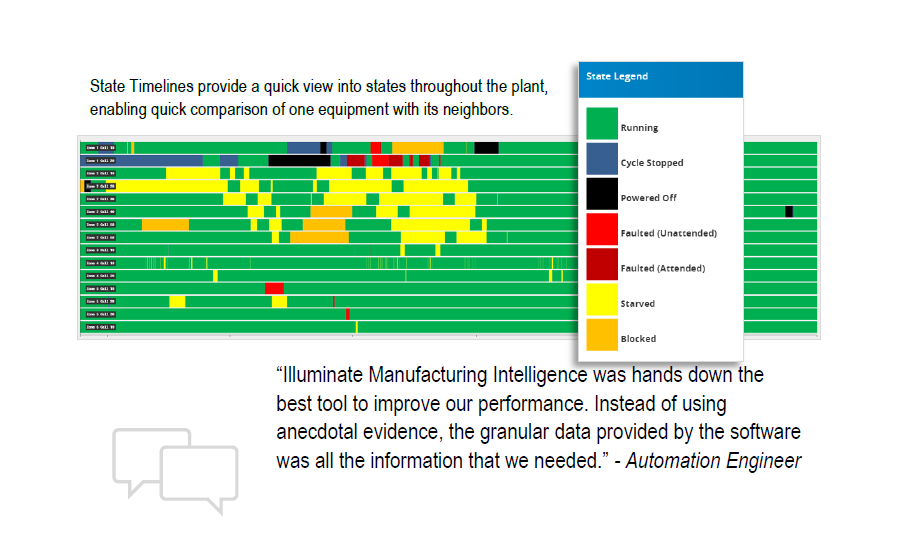

Through detailed Production Summaries, JuanaRoll identifies and prioritizes key factors affecting OEE and MOEE—highlighting the Top 5 losses and guiding targeted improvement actions. The State Timelines feature offers a clear visual of system activity, mapping transitions between operating, idle, and fault states to expose bottlenecks and improve response times.

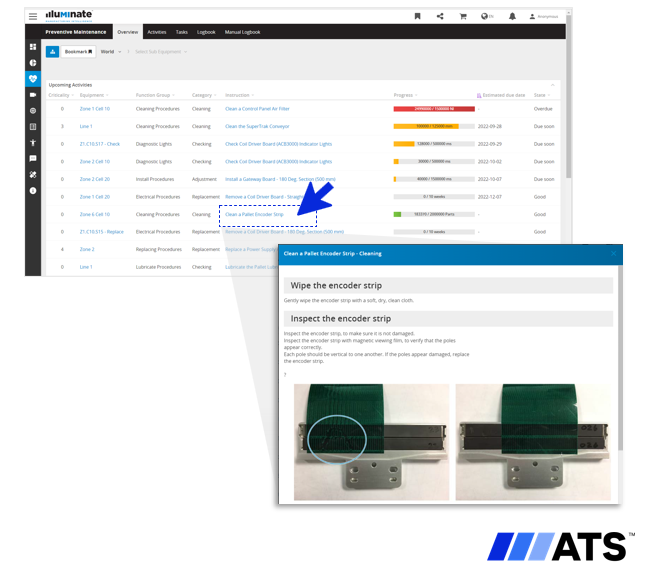

Accelerating Preventive Maintenance and Uptime

Illuminate empowers JuanaRoll’s maintenance teams with early fault detection and trend-based insights. By analyzing Fault Reports and Reject Summaries, teams can identify recurring issues and determine whether they stem from specific equipment, components, or operational patterns. This predictive visibility allows maintenance to act before problems escalate, reducing unplanned downtime and extending equipment lifespan.

Additionally, Notifications and Scheduled Reports deliver real-time alerts and automated summaries, ensuring maintenance tasks are completed on time and potential risks are addressed before they disrupt production.

Seamless Collaboration and Knowledge Sharing

With Operator-to-Operator Messaging, shift teams can log comments, flag issues, and leave instructions directly in the system, expediting knowledge transfer and coordination. This continuous feedback loop keeps operations synchronized and minimizes information loss between shifts.

Driving Continuous Improvement

“ATS Illuminate gives us the clarity and confidence to run our operations smarter,” said Mark Conforti, Director of Operations & Aftermarket at Paxiom Group. “Instead of reacting to problems, we’re now anticipating them—turning data into foresight that keeps our lines running and our products consistent.”

Media Contact:

Val Miller

Marketing Manager – Content & Events