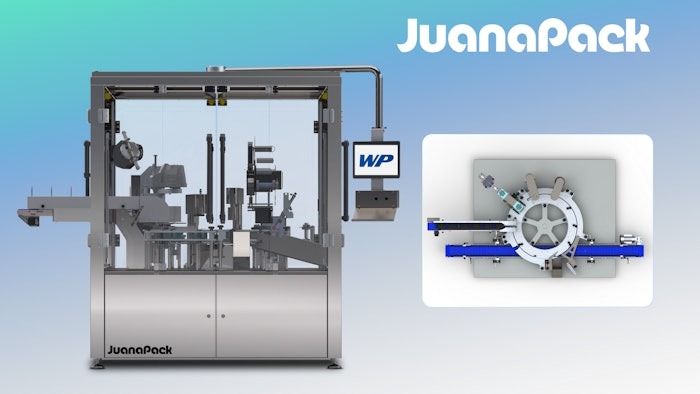

Canapa by Paxiom will be turning heads at MJBizCon with the global premiere of JuanaPack, an advanced, purpose-built automation system engineered for pre-roll tube loading and tray filling, and designed as the backbone of a full, turnkey packaging line — from pre-roll to pallet.

JuanaPack: Precision, Speed & Flexibility

At its core, JuanaPack is a state-of-the-art rotary loading system that automatically indexes rigid pre-roll tubes or trays, orients each pre-roll, and fills with surgical precision.

Key loading features include:

- Automated tube or tray loading

JuanaPack can be configured to load into tubes or tray formats, giving operators flexibility to support different packaging styles. - Orientation control

The system uses a built-in mechanism to orient pre-rolls properly before placement to ensure clean, consistent presentation. - Capping

Compatible with slide caps, screw caps, and pop-top caps — fully automated capping ensures secure and compliant container closure. - Custom pack patterns for trays

For tray loading, JuanaPack supports a variety of pack layouts — upright, inverted, staggered — tailored to your format needs. - Optional labeling

You can add a tube-labeling module so that your packaged pre-rolls are retail-ready right off JuanaPack.

Seamless Integration with Other Paxiom Systems

While JuanaPack handles loading and orientation, it doesn’t stand alone — it’s built to plug into Paxiom’s broader automation ecosystem. The JuanaPack can be seamlessly combined with:

- JuanaRoll

The high-speed pre-roll machine that weighs, fills, compacts, twists, and trims pre-rolls — generating consistent, high-throughput quality pre-rolls. - Vision360

A 360-degree inspection system that detects imperfections in each pre-roll (tears, cuts, color variation, twist anomalies, and more) before it’s packaged. - WeightCheQ 0-250

A high-precision check-weigher that can validate each pre-roll or package to ensure compliance with regulatory weight tolerances. Sensitivity to 0.001g! - Robotic Tray Loading

JuanaPack can work with a SCARA robot to gently “pick and place” pre-rolls into trays, respecting the pack pattern you define. - Case Forming & Case Packing

After tube or tray loading and labeling/capping, Paxiom end of line machines can form cases or trays, automatically pack them using robotic case-packing modules, and seal the cases. - Palletizing

To finish the line, Paxiom offers full palletizing — stacking cases onto pallets for shipment, creating a true “product-to-pallet” automated solution.

Why JuanaPack Is a Game-Changer

- Labor Reduction: Automating the most manual, repetitive part of pre-roll production (tube/tray loading) significantly reduces reliance on hand labor.

- Scalability: With its modular architecture, JuanaPack grows with your business — from just loading to a fully integrated line with inspection, capping, labeling, case packing, and palletizing.

- Quality & Compliance: Through Vision360 and check-weighing, you get real-time quality assurance, protecting both product integrity and regulatory compliance.

- Packaging Flexibility: Whether you’re distributing single pre-rolls or multi-pack trays, JuanaPack adapts to your format demands.

- Turnkey Automation: Paxiom’s engineering services can build a full factory footprint around your JuanaRoll + JuanaPack setup — optimizing line flow from pre-roll creation all the way to pallet.

See It Live at MJBizCon

Visit Canapa by Paxiom at Booth C-21607 during MJBizCon to experience JuanaPack and many more new innovative cannabis packaging machines in action!

About Canapa by Paxiom

Canapa, the cannabis-automation division of Paxiom, specializes in designing, building, and integrating packaging systems tailored to the legal cannabis market. From pre-roll filling and inspection to retail-ready packaging and end-of-line automation, Canapa delivers robust and scalable solutions engineered for cannabis producers.

For press, demo, or partnership inquiries:

Val Miller | valm@canapasolutions.com